The Maintenance of the Roller Heat Press Machine

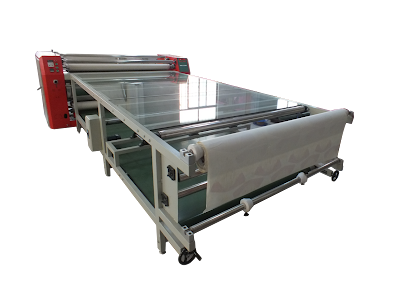

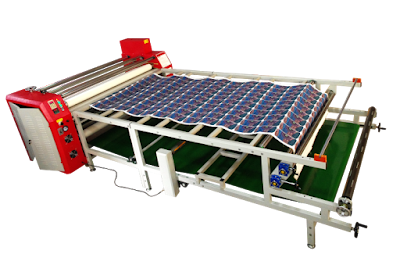

Roller heat press machine is the machine which can help people improve the productivity in sublimation printing. Learning some essential maintenance methods for the roller heat press machine can guarantee the quality of the products and service life of the machine. Then, how to maintain the machine?

1. What should we do when the machine breakdown?

The machine could occur breakdown during working, breakdown handling can be divided into two types: non-stop working and stop working.

1). Handling of non-stop working breakdown:

A. When finding heating blanket with small stuff, you can clean it with brush. If can not, you can removed it when it stops.

B. When finding blanket with small stripes, you can use small stone to grind it . If can not, you should send it to repair. But it’s seldom to appear such problem.

C. If you find color difference between both sides and middle place, you can adjust the pressure on both sides, or adjust the space between roller drum and blanket.

D. If you find the parts are loosing during working, you should fasten the screw in time.

E. If you find heating press with false designs, you can slow down the machine.

F. When finding the blanket and conveyor belt deviate to one side, you can adjust manually, and our roller heat press machine has automatic function of deviation correction for blanket and conveyor belt..

G. When finding the fabric with staining, you should turn on drying system to dry the fabric and avoid the staining.

F. When finding the blanket and conveyor belt deviate to one side, you can adjust manually, and our roller heat press machine has automatic function of deviation correction for blanket and conveyor belt..

G. When finding the fabric with staining, you should turn on drying system to dry the fabric and avoid the staining.

H. When finding the fabric or blanket tension is too strong or too small, you should adjust the speed between units or tension device in time, make sure proper tension.

I. When the moisture is uneven of fabric, you could adjust the pressure.

2). The handling of stop working breakdown:

A.If some sharp material into the roller, stop it and take it out.

B.During heat transfer, if find fabric too much thread, and wind into the roller, you should stop machine and deal with it in time.

C. When the blanket used for long time, and blanket too thin,heating not steady, you should stop machine and take out to change a new one.

2. Machine maintenance:

A.Check screws, parts, roller, axis, blanket etc frequently.

B. Before operating roller heat press machine, you need to make oil to the active parts

C.Clean the machine every week.

A roller heat press machine is very important for the sublimation printing, and learn to maintain it by yourself can help you save a lot of money, why not?

More information:

Website: www.ink-sublimation.com

E-mail: sales@ink-sublimation.com

Whatsapp: +86 18105155024

*************************************************

Follow us:

评论

发表评论