Several Tips for Inkjet Sublimation Transfer Paper Printing

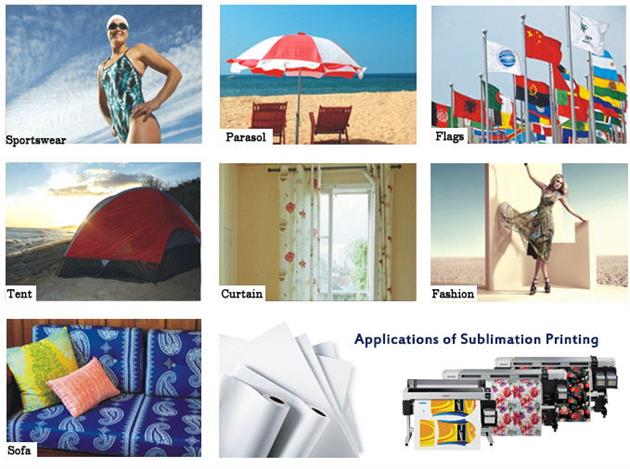

How much do you know about inkjet sublimation transfer paper printing?Do you know what should pay attention to when sublimation transfer printing?Today,we will share several tips for inkjet sublimation transfer paper printing.

a) The humidity of the printing environment is preferably controlled to 45 to 70% RH. If the air is too dry, the transfer paper warps easily. At this time, when the large ink amount is printed, the transfer paper absorbs water and elongates and arches may cause friction. Sprinkler failure; if the air is too humid, it will cause the drying speed to drop and the two ends of the transfer paper will not be stretched. Please install and activate the air-conditioner in the inkjet printing room, and it is possible to stably print with ink under stable environmental conditions. If there is no constant temperature and humidity in the air conditioner, the remedy is to remove the plastic bag from the transfer paper 1-2 days before printing so that the transfer paper can breathe in the exposed air and balance the water in the transfer paper. The purpose of this is to make the transfer. The printing paper absorbs moisture and is pre-elongated to prevent the dry transfer paper from excessively absorbing the printing ink and elongating it.

b) When the environmental humidity is very high, the original paper layer of the transfer paper may be uneven due to uneven absorption of water on both sides. In this case, the print pattern will run out or the paper jam will wrinkle. A clean steel tube may be placed across the side of the printer on the feeding side and the unwinding, and appropriate weights may be attached to both ends of the steel tube so that the transfer paper is maintained in a flat and proper tension.

c) When the transfer paper absorbs too much water in the air, the paper becomes very soft, so that the transfer paper easily wrinkles when passing through the pickup roller. The remedy is to remove some pickup roller springs at intervals. Reduce the pressing force to keep the printer flat.

d) To confirm the printing surface of the transfer paper, the printing surface of the package transfer paper is facing outwards. When the printing surface cannot be determined, the two sides of the transfer paper can be smeared with the fingers and the clean water. Is the print surface.

e) When placing the transfer paper on the printer, wear fine cloth gloves to prevent the transfer paper surface from being dirty fingerprints.

f) When renewing a new volume, it is safe to first print a small block of standard color (the standard color block refers to the familiar CMYK four-color or six-color pattern) and do the transfer test to ensure that each The color of the roll paper is the same. If there is a clear color difference, it is necessary to find the cause and eliminate it in time.

g) During the printing process, test strips shall be used to ensure the smoothness of the ink on the print head, so that the color of the pattern is consistent and accurate, and printing defects are avoided due to partial blockage of the print head.

h) In the case of rewinding while printing, press the print volume of the print pattern, turn on the printer's built-in heater and set a suitable temperature, or turn on the external air-drying device. Make sure that the back of the roll is not stained during the rewinding process to avoid blemishes.

We supply many kinds of sublimation transfer papers.If you have any demand,please feel free to contact us.Thanks for your reading!

More information:

Website: www.ink-sublimation.com

E-mail: sales@ink-sublimation.com

评论

发表评论