Meltblown Fabric for Face Mask Structure

Meltblown Fabric for Face Mask Structure

It needs to be recognized that home melt-blown non-woven fabric has been pretty niche, with an annual manufacturing capability of 53,500 tons, accounting for 1% of the non-woven manufacturing capacity. They are generally used to produce masks, environmentally pleasant materials, clothing, battery separators, and different products. Non-permanent growth is slow. This is ordinarily due to the trouble of lengthy shipping cycle of manufacturing gear and excessive technical necessities for personnel operation. It is challenging to shortly extend the manufacturing ability of melt-blown fabric in a quick time.

Melt-blown cloth, the full title of melt-blown non-woven fabric, is a key cloth for bringing virus filtering impact to masks. It has ultra-fine fibers with static electricity. In addition to blocking off large dirt particles, it can additionally appeal to satisfactory dust, micro organism, and viruses via the static cost on the surface.

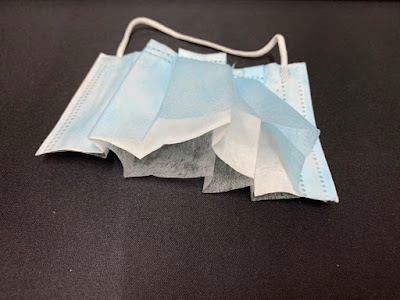

Medical masks normally undertake a multi-layer structure, referred to as SMS structure: a single layer of spunbond layer (S) inner and outside, a single layer, or a couple of layers of meltblown layer (M) in the middle, meltblown material is the fine melt-blown layer material. Meltblown material is a sort of non-woven fabric.

Non-woven fabrics, additionally regarded as non-woven fabrics, are composed of oriented or random fibers, besides warp and weft, and are named due to the fact of their look and sure houses comparable to woven fabrics. There are many processing methods for non-woven fabrics, such as spunbond, melt-blown, hot-rolled, spunlace, etc. Among them, the non-woven cloth made via melt-blown approach is known as melt-blown non-woven fabric. The melt-blown approach refers to a spinning technique in which a polymer soften that has simply been extruded is unexpectedly stretched and solidified via high-speed hot air flow. The non-woven material produced by using the melt-blown technique has finer fibers, large floor area, and higher filtering, shielding, warmth insulation and oil absorption properties, which are unmatched by means of non-woven fabric produced by means of different processes.

Therefore, the melt-blown fabric is used in scientific and industrial masks production, and can additionally be used in many fields such as thermal insulation materials, filter materials, clinical and hygienic materials, oil-absorbing materials, wiping cloths, battery separators and even sound insulation materials. There are no longer many home large-scale manufacturers successful of producing melt-blown fabrics, and the enterprise as a total suggests a small and scattered situation. The enterprise has a lengthy lacked interest and has been tepid.

★More info★

Website: www.feiyuepaper.com

Whatsapp/Wechat:008613776614520

Email:sales@feiyuepaper.com

Skype: li.sunny282

If you have any questions, call me, let's talk about the details.

★Follow Us★

Facebook: https://www.facebook.com/onestopsublimationsolutions/

Linkedin: https://www.linkedin.com/company/sublimation-skyimage/

Twitter: https://twitter.com/sublimateprint

Pinterest: https://www.pinterest.com/sublimationpaperprinting/

Youtube: https://www.youtube.com/channel/UCvfhRcVPCNVm0YTdCCORPbw

Vk: https://vk.com/id324602723

Blogspot: https://sublimatestar.blogspot.com/

评论

发表评论