Factors Of Effecting Sublimation Paper Quality

Factors Of Effecting Sublimation Paper Quality

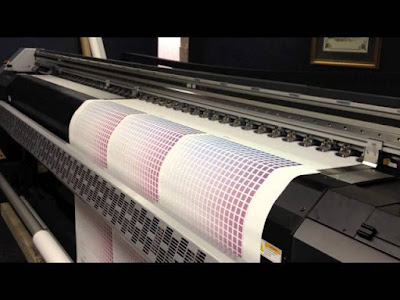

With the non-stop improvement of digital thermal transfer technology, one of its principal consumables, sublimation switch printing paper, has grown to be a warm spot in the material printing and paper enterprise in latest years. In the past, the sublimation switch printing paper in most cases relied on imports from South Korea and the Netherlands, and now China has additionally ended up a fundamental producer of Sublimation Paper. Transfer printing paper can be divided into water switch printing paper and warmth switch in accordance to its switch method.

There are two most important kinds of printing paper, amongst which the warmness transfer paper is divided into sublimation transfer paper and movie thermal switch paper. In view of the performance traits and utility necessities of sublimation switch printing paper, the predominant elements affecting the switch impact and switch first-rate of sublimation switch paper had been studied, and the switch precept of sublimation paper was once summarized.

Performance necessities and primary checking out indications of sublimation paper

The overall performance necessities of sublimation transfer paper are now not uniform in China, and there is no standardized specific inspection instrument. However, some massive overseas manufacturers, such as Hansol of South Korea, Jetcol of Netherlands, etc., have some set of personal cease users. Detection capability to strictly manage product quality. There are no longer many home research in this field. Through the evaluation of imported merchandise and the necessities of home customers [1], it is believed that the pleasant necessities and overall performance assessments of sublimation switch printing paper can be commenced from the following aspects:

1.1 Print quality

Print excellent refers to the standard impact of a printed photograph on paper. The sublimation switch printing paper requires that the printed photograph has accurate ink absorption, uniform absorption, quick absorption of ink droplets, and no apparent ink accumulation and picture bleed after printing. If the picture print fine is poor, the ink absorption of the coating is no longer good, the absorption is no longer uniform, and the bleed phenomenon is extra obvious. The enamel on the printed photo will be greater apparent on the switch product, and the familiar overall performance of the paper can't rapidly take in the ink. The ink phenomenon is severe, and the printed picture is effortlessly scratched or destroyed for the duration of non-stop production, affecting the switch yield and non-stop manufacturing twist.

1.2 Transfer quality

The switch satisfactory ability that the photograph is printed on the sublimation transfer paper. Under positive switch conditions, the picture ought to be transferred to the substrate as totally as viable after the thermal transfer, and the transferred photograph is complete, realistic, and the coloration density value. High, the boundaries between distinctive colors are clear, there is no ghosting phenomenon, and the quantity of ink last on the paper ought to be as small as possible. The approach adopted is to print the picture in the equal inkjet printer and in the identical printing mode. After the transfer, the ordinary impact of the transferred product photo and the quantity of residual ink on the paper are used to choose whether or not the paper is right or not. Specifically, the basic impact of the switch product (including shade uniformity, clear boundaries between colors, etc.) and the size of the CMYK coloration optical density cost of the transferred switch product photograph and the residual picture on the paper by means of a reflection densitometer are observed. Density cost is used to indicate. The normal impact of the transferred photo is good, the common price of the sum of the optical density values of the number of colorations is high, the common density fee of the residual color on the paper is low, the residual ink quantity is small, and the paper satisfactory is better.

1.3 Paper shape stability

Paper structure balance generally refers to the deformation of paper in regular indoor surroundings and the thermal steadiness in excessive temperature surroundings (180~230°C). If the sublimation switch paper is deformed in an everyday indoor environment, the paper can't be sufficiently and intently contacted with the substrate (such as cloth) at some point of the non-stop switch manufacturing process, affecting the switch quality, and may additionally purpose a change. Printed product photo ghosting phenomenon. The paper has a negative balance underneath excessive temperature surroundings (180~230°C), handy to age, and the power is deteriorated. It is effortless to ruin the paper throughout the switch manner and have an effect on the production. The precise assessment technique is to choose the balance of the paper underneath normal indoor surroundings beneath the situation of positive humidity and temperature, the diploma of curling of the paper in a sure duration of time; the tensile electricity of the paper beneath unique excessive temperature environments (180~250°C) And tear energy to choose the balance of paper in excessive temperature environment.

★More info★

Website: www.feiyuepaper.com

Whatsapp/Wechat:008613776614520

Email:sales@feiyuepaper.com

Skype: li.sunny282

If you have any questions, call me, let's talk about the details.

★Follow Us★

Facebook: https://www.facebook.com/onestopsublimationsolutions/

Linkedin: https://www.linkedin.com/company/sublimation-skyimage/

Twitter: https://twitter.com/sublimateprint

Pinterest: https://www.pinterest.com/sublimationpaperprinting/

Youtube: https://www.youtube.com/channel/UCvfhRcVPCNVm0YTdCCORPbw

Vk: https://vk.com/id324602723

Blogspot: https://sublimatestar.blogspot.com/

评论

发表评论