UV printer market will get better and better?

UV printer market will get better and better?

Compared with the UV printer of previous years, UV printers have improved many faults at this stage, and their performance has become stronger. UV printers are also known as universal printers, and the market demand has become greater. Although UV printers still have certain disadvantages, many entrepreneurial investors do not care about their prices and disadvantages, and at the same time resolutely decided to invest in UV printers. To this end, innovate their own products to promote the development trend of the entire industry. So compared to the UV printers used in earlier years, what are the advantages of today's UV printers? What are their characteristics? Today I will briefly explain to everyone.

First,in the previous UV printers, all raw materials except for the real leather had to be coated before printing. In order to improve the adsorption of raw materials by the printing ink. Today's UV printers, except for the relatively high density of printed glass and metal materials, need to be spray-coated for the raw materials of very lightmaps. Other raw materials can be printed immediately without coating.

Second, the increase in printing speed: In the past, UV flatbed printers used epson printheads, with one printhead and 8 colors, so the print speed was relatively low during the execution of the program. Today's UV printers use Ricoh print heads, with one print head and one color. Both the speed and reliability are higher than epson UV printers.

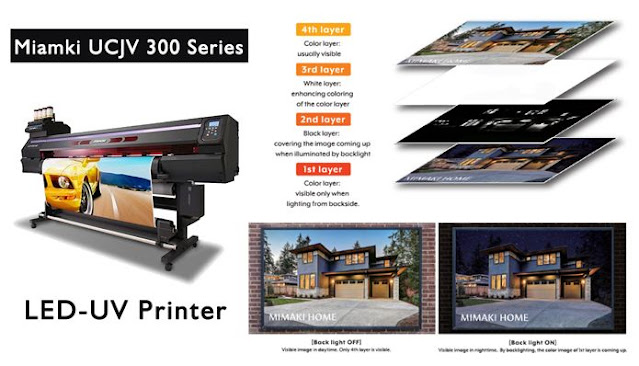

Third, the difference in actual results: the previous UV inkjet printer can only print color, there is no way to print white. At the same time, the UV printer uses a weak solvent printing ink, which can only print the actual effect on the plane, but not the actual effect of the three-dimensional effect of the relief. Today's UV printers can print both white and relief!

Fourth, the drying process: In the previous UV printers, mechanical drying was required after printing, so that the printing ink can be completely dried, but today's UV printers do not need mechanical drying, because it uses the UV curing lamp pair The UV printing ink is dried at once.

★About us★

We are professional "One-Stop" Sublimation Printing Equipment supplier, including Large Format Printer, Heat Press Machine and PET Film Printing Machine.

★More info★

Website: www.feiyuepaper.com

Whatsapp/Wechat:008613776614520

Email:sales@feiyuepaper.com

Skype: li.sunny282

If you have any questions, call me, let's talk details.

★Follow Us★

Facebook: https://www.facebook.com/onestopsublimationsolutions/

Linkedin: https://www.linkedin.com/company/sublimation-skyimage/

Twitter: https://twitter.com/sublimateprint

Pinterest: https://www.pinterest.com/sublimationpaperprinting/

Youtube: https://www.youtube.com/channel/UCvfhRcVPCNVm0YTdCCORPbw

Vk: https://vk.com/id324602723

Blogspot: https://sublimatestar.blogspot.com/

评论

发表评论