Four attention for UV inkjet printers in winter

Four attention for UV inkjet printers in winter

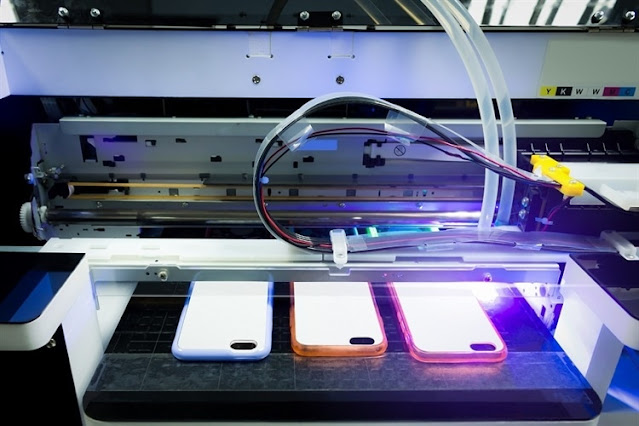

Every year when the winter gets cold, the number of failures of UV inkjet printers will also increase, mainly in 4 aspects: print head blocked and disconnected, consumables solidify and condense, electrostatic interference, and unstable voltage. How to prevent these situations in advance.

The matters needing attention are as follows

1. Print head blocked and disconnected

After the temperature is lowered in winter, the nozzle will appear “clogged and disconnected”, so don’t worry too much. This is mostly because the UV ink's viscosity increases and the fluency decrease after the temperature of the UV ink decreases. Smooth result.

Solution: In addition to the conventional large ink cartridges and second-class ink cartridges that are automatically stirred and warmed, heating plates can be installed on both sides of the ink outlet of the print head. If it is not convenient to install, you can choose a small sun from a certain east and a certain treasure and keep it 30 cm The distance to the headlight car, if possible, you can turn on the heater or air conditioner to keep the working environment temperature of the UV printer above 25 degrees.

2. consumables solidify and condense

Some UV printer users found that the ink in the UV ink bottle became thick and some had condensed. When this happens, the ink has been discarded and cannot be used, mostly because the ink bottle is placed directly on the ground.

Solution: The storage of winter consumables needs to be placed on the shelf, not on the ground, or placed in the open air.

3. electrostatic interference

In winter, the wetlands of the air are reduced, and after the dust is increased, static electricity often occurs. The direct effect is that the ejected ink droplets deviate from the direction due to static electricity, causing "flying ink" or "splatter ink" phenomenon, and the print quality will be seriously reduced. In severe cases, the circuit will be burned.

Solution: In addition to installing the necessary ground wire, the working environment of the UV printing machine needs to be maintained for 2 days / time to reduce dust. If the air is dry, just turn on the humidifier. If possible, an electrostatic rod can be installed on the machine to eliminate static interference from the material itself.

4. Unstable voltage

In winter, due to heating demand, a large number of electrical appliances will be turned on, and current and voltage will be overloaded. These instability, light will affect the normal operation of digital UV printer, and in other words, it will directly burn the internal circuit.

Solution: In addition to selecting a regular manufacturer's UV printer (the circuit system has preventive and emergency resolution devices), a voltage regulator must be installed, a backup power supply must be installed, and independent lines must be installed for the device. It cannot be mixed with other electrical appliances.

More info:

Website: www.feiyuepaper.com

Whatsapp/Wechat:008613776614520

Email:sales@feiyuepaper.com

Skype: li.sunny282

If you have any questions, call me, let's talk about details.

Follow Us:

Facebook: https://www.facebook.com/onestopsublimationsolutions/

Linkedin: https://www.linkedin.com/company/sublimation-skyimage/

Twitter: https://twitter.com/sublimateprint

Pinterest: https://www.pinterest.com/sublimationpaperprinting/

Youtube: https://www.youtube.com/channel/UCvfhRcVPCNVm0YTdCCORPbw

Vk: https://vk.com/id324602723

评论

发表评论