The difference between dye sublimation and direct dye-sublimation

The difference between dye sublimation and direct dye-sublimation

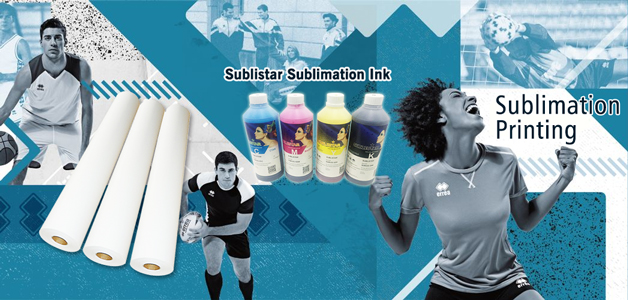

As we all know, dye-sublimation printing popularly used on much kind fabric. This kind of printing is very easy and with a perfect transfer effect. And then appeared another printing - direct sublimation transfer printing. Do you know the difference between them? Please read the following, I will share with you more.

What is dye sublimation printing? Dye-sub printing requires heat—the act of sublimation occurs when the inks are warmed, turn into a gaseous state, and permeate the substrate. With direct dye-sub, the sublimation process occurs directly on the fabric. With transfer dye-sub, a graphic is first printed onto sublimation paper and then infused on the fabric through an external heat source. Although the transfer and direct methods differ, they also share many common benefits. Here, Digital Output explores the applications and situations when it’s advantageous to use dye-sub for fabric printing. We also highlight dye-sub printers and ink.

Benefits of Dye-Sub No printing method fits every application, and each approach and technology offers benefits. However, dye-sub is a go-to method of fabric printing for durability and color. Dye-sub delivers a wide and vivid color gamut, often with only four colors. It’s easier for the print provider to capture and replicate the nuances of the graphic.“This level of saturation produces superior output and a high-quality appearance. Sublimated fabrics can also be stretched into an infinite number of shapes and forms so the only limitation is the imagination. Other technologies will see cracking and crazing with stretching and folding,” he observes.

Dye-sub is appropriate for both long- and short-term applications. The two dye-sub methods each have unique benefits. Some print providers prefer to transfer dye-sub, finding it easier to print directly on sublimation transfer paper rather than on fabric. Transfer doesn’t have the same UV resistance as some printing methods, so it’s not used as often for outdoor applications. However, it offers a rich, deep color that makes it popular for many other uses and settings. “Dye-sub transfer, because of its high definition and color pop, is preferred for indoor signage, home decoration fabrics,” shares Epson. And Epson adds that transfer provides sharper images and contours that are ideal for applications in this segment.

★About us★

We are a sublimation paper professional supplier. Our company can supply any need for sublimation transfer paper, sublimation ink, printer, Epson ink, heat transfer paper, Roll calendar machine for textile printing! www.feiyuepaper.com

★More info★

Website: www.feiyuepaper.com

Whatsapp/Wechat:008613776614520

Email:sales@feiyuepaper.com

Skype: li.sunny282

If you have any questions,call me,let's talk details.

★Follow Us★

Facebook: https://www.facebook.com/onestopsublimationsolutions/

Linkedin: https://www.linkedin.com/company/sublimation-skyimage/

Twitter: https://twitter.com/sublimateprint

Pinterest: https://www.pinterest.com/sublimationpaperprinting/

Youtube: https://www.youtube.com/channel/UCvfhRcVPCNVm0YTdCCORPbw

Vk: https://vk.com/id324602723

Blogspot: https://sublimatestar.blogspot.com/

评论

发表评论